GLASS & ALUMINUM

BLOG

Metal Mesh Laminated Glass: Strength and Fashion Combined

In the modern age of cutting-edge architecture and interior design, glass is no longer simply a transparent seal, it's a statement piece. One of the most striking innovations in building materials is metal mesh laminated glass, a product that combines perfectly structural integrity with sleek sophistication. Used in facades, partitions, or even decorative panels, metal mesh glass adds the stylish touch that makes the luxury interior and modern building what it is.

Let's see what metal mesh laminated glass is, how it is manufactured, and why it has become a favorite among designers and architects looking for both form and function.

What is Metal Mesh Laminated Glass?

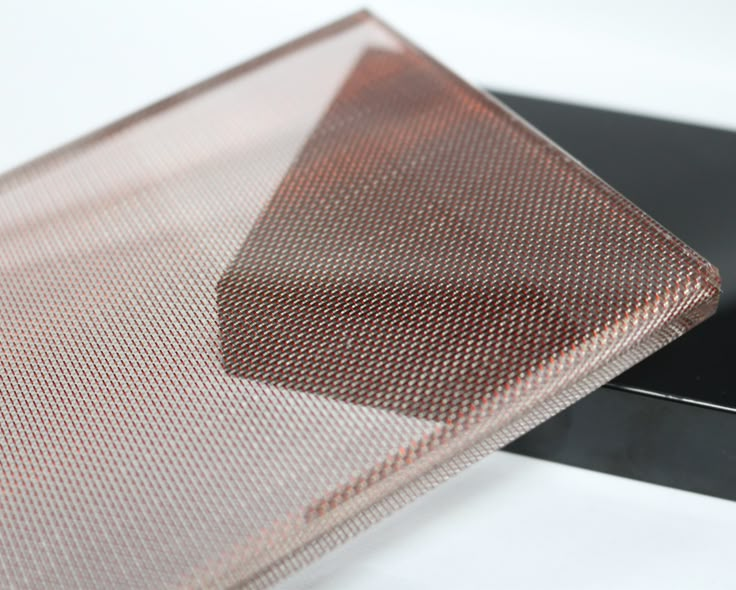

Metal mesh laminated glass is a decorative and safety glass product made by infusing a thin metal mesh between two or more glass substrates through high-temperature lamination. The outcome is a single, robust, and visually rich panel that brings together the transparency of glass with metal strength and texture.

The metal mesh composed of materials like stainless steel, aluminum, bronze, or copper is placed in the middle of the layers of glass to form a dramatic interplay of texture, reflection, and transparency. This renders laminated glass metal mesh both an aesthetically pleasing as well as functional architectural element.

By combining industrial materials with cutting-edge glass technology, metal mesh lamination provides a distinct look, slender, tough, and extremely modern.

The Process Behind Metal Mesh Lamination

Production of metal mesh laminated glass requires precision engineering and the latest lamination processes. Metal mesh lamination ensures that the glass is durable, safe, and optically clear while providing perfect encapsulation of the metallic mesh.

This is a basic rundown of the process:

- Material Selection: Designers select the metal mesh type (stainless steel, brass, copper, etc.) depending on texture, color, and transparency requirements.

- Glass Preparation: Clean, high-quality glass sheets are prepared for lamination to allow perfect bonding.

- Lamination Process: The metal mesh is sandwiched between glass sheets and a clear interlayer like EVA or PVB. The structure undergoes controlled pressure and heat in an autoclave.

- Cooling and Finishing: After bonding, the glass panel is cooled, inspected, and finished for ultimate visual quality.

Professional metal mesh laminating services guarantee perfect register, no air bubbles, and high adhesion giving a glass that's as stunning as it is durable.

Why Metal Mesh Laminated Glass is Trending

-

Strength and Durability

The very first and primary advantage of metal mesh laminated glass is its outstanding strength. The infused metal layer provides reinforcement, which renders it significantly more shock-absorbing than regular laminated glass. Upon shattering, the interlayer keeps the fragments in place, minimizing injury and property loss.

The suitability of metal mesh glass for high-traffic locations, facades, balustrades, and other applications requiring both safety and stability makes it perfect for such uses.

-

Unique Aesthetic Appeal

One of the main reasons architects are fond of laminated glass metal mesh is its unique visual quality. The metal texture contained inside the glass bounces light in interesting patterns, adding depth and dimension. Depending on the mesh and weave of the mesh, the glass can appear sleek and industrial or soft and refined.

Designers prefer metal mesh laminated glass to design feature walls, partitions, and ceilings that go in the direction of luxurious and futuristic interiors. The material looks stunning with stone, wood, or concrete and provides contrast and sophistication to the environment.

-

Privacy with Light Transmission

Unlike other opaque materials, metal mesh glass provides transparency with partial visual screening. The density of the mesh may be modified to provide the needed level of privacy.

This makes metal mesh laminated glass ideal for office partitions, hotel lobbies, and home interiors where you desire free flow of light without visibility. The result is both an open and private space — a refined balance that's extremely desirable in contemporary design.

-

UV and Weather Resistance

Another factor behind the increasing need for metal mesh lamination is its ability to perform in extreme environmental conditions. The laminated design offers UV resistance, shielding interiors from fading and keeping the glass strong in the long term.

Used in external applications, metal mesh laminated glass can resist temperature changes, moisture, and corrosion particularly with the application of stainless steel or treated aluminum meshes. It is, therefore, perfect for indoor as well as outdoor architectural work.

-

Fire and Safety Performance

Some forms of metal mesh laminated glass have improved fire resistance. The metal provides even heat distribution and reduces flame spread, providing extra safety in the event of a fire.

Coupled with its shatterproof advantage, this makes metal mesh glass an intelligent option for buildings that value both aesthetics and security like commercial centers, hotels, and public facilities.

Applications of Metal Mesh Laminated Glass

-

Building Facades

One of the best uses of metal mesh laminated glass is in building facades. It forms a dramatic, reflective surface whose appearance varies with lighting conditions and angle of view. In commercial high-rises, it brings added sophistication without impairing functional benefits such as glare reduction and solar control.

-

Interior Partitions and Walls

In malls, offices, and high-end homes, laminated glass metal mesh partitions delineate spaces without surrendering openness. The metallic designs in the glass provide interiors with an upscale, artistic touch.

-

Balustrades and Staircases

For contemporary architectural staircases and balconies, metal mesh laminated glass combines elegance with safety. The strengthened mesh provides it with structural strength, while the glass ensures the design remains minimal and transparent.

-

Ceilings and Skylights

Designers are making greater use of metal mesh glass in ceilings and skylights to produce striking lighting effects. The mesh screens sunlight, creating dynamic patterns and reflections across the room.

-

Art Installations and Decorative Panels

As a decorative element, metal mesh laminated glass creates limitless possibilities. From reception backgrounds to hotel lobby walls, it's a material that converts any surface into a modern design statement.

Benefits Over Conventional Laminated Glass

- Increased Strength: The metal reinforcement enhances structural strength.

- Aesthetic Design: Aesthetic textures and reflective finishes provide artistic impressions.

- Better Privacy: Mesh density can be adjusted for privacy without compromising on light transmission.

- Durability: Better UV, corrosion, and environmental resistance.

- Security: Shatterproof structure minimizes threats during breakage.

These benefits render metal mesh lamination services a popular favorite among architects and home owners alike who are looking for innovation and sophistication.

Metal Mesh Lamination Options

One of the most attractive features of metal mesh laminated glass is that it can be customized. Designers can personalize:

- Mesh Material: Select stainless steel, copper, brass, or aluminum for varying tones and textures.

- Mesh Pattern: Fine weaves, perforations, or striking geometric patterns.

- Transparency Level: Vary density to regulate light transmission and privacy.

- Glass Type: Pair with clear, tinted, frosted, or low-iron glass for different aesthetics.

Expert metal mesh lamination services can customize each aspect from color to reflection to fit your architectural vision.

Maintenance and Longevity

Metal mesh laminated glass is built for long-lasting performance with little upkeep. Its sealed design keeps dust or moisture from penetrating to the embedded mesh, providing permanent clarity and beauty. Cleaning with gentle solutions is the only maintenance required to keep the surface like new.

Moreover, due to its extreme wear, corrosion, and UV resistance, metal mesh glass retains its looks even in exposed or high-humidity conditions.

Final ThoughtsMetal mesh laminated glass is the ultimate union of engineering and art. It combines the industrial might of metal with the beauty and transparency of glass to create a product that is both functional and aesthetically pleasing.

No matter if applied to commercial buildings, residential spaces, or art installations, laminated glass metal mesh brings every project to new heights with its contemporary look and unbeatable versatility.

By consulting with seasoned metal mesh lamination services, property owners and designers are able to gain customized solutions that embody innovation, durability, and sophistication.

In a technology-meets-design world, metal mesh laminated glass is the face of modern luxury — where strength is matched by style, and architecture is art.