GLASS & ALUMINUM

BLOG

Cost Factors to Consider When Choosing Metal Mesh Lamination Services

Modern architects, interior designers, and contractors wanting to mix durability with aesthetic refinement are increasingly turning to metal mesh laminated glass. It is however imperative to be aware of the cost considerations related in planning to include metal mesh lamination into your glass products.

Choosing a lamination provider only on cost can result in overspending or worse, underperformance, whether you are designing an interior partition, a commercial façade, or a custom design component. At SafinGlass, we assist you in skillfully balancing cost, quality, and design expectations.

This guide divides the primary cost factors you should take into account while selecting metal mesh lamination services for your project.

What is Metal Mesh Lamination?

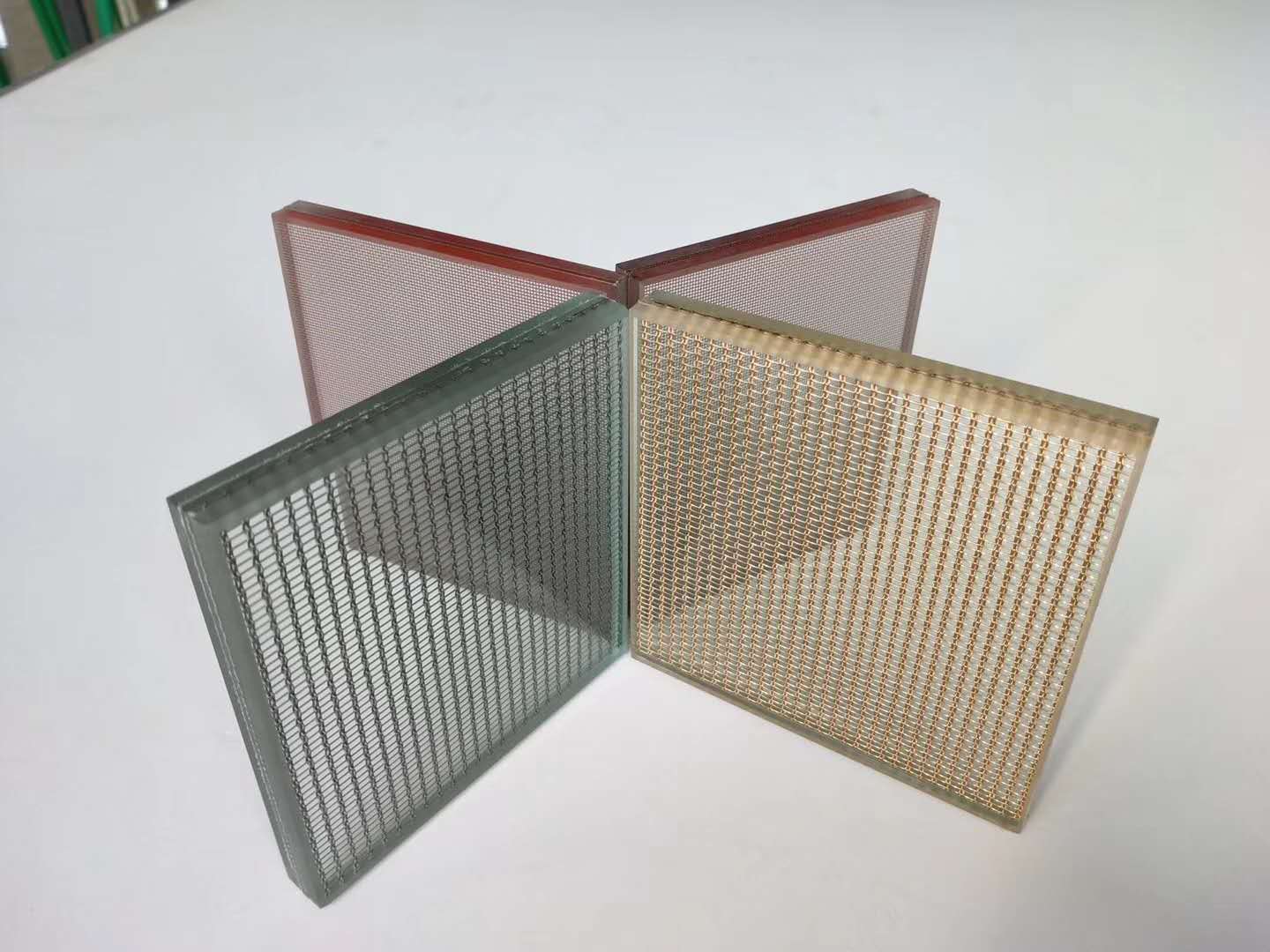

Before we go into cost elements, let's concisely define it. Embedding a small ornamental metal mesh (such stainless steel, copper, or bronze) between two layers of glass using a lamination interlayer like PVB or EVA creates metal mesh laminated glass. This offers privacy, UV protection, and strength in addition to improving looks.

Let's now examine what affects cost structure.

1. Material Matters: Type of Metal Mesh

Metal mesh comes in forms from simple stainless steel to decorative bronze or even custom embossed copper. The price changes depending on:

Mesh density and gauge

Matte, mirror, brushed finish types.

Manufacturer (imported vs. local)

Qualities of resistance to corrosion

Tip: Choose basic stainless steel mesh with a brushed finish, it provides longevity without expensive customising charges, if you are on a budget.

2. Glass type and thicknessSpecifications for glass vary:

Clear float glass is most inexpensive.

Low-iron glass (ultra-clear) is more expensive but has exceptional clarity.

Heat-strengthened or tempered glass costs more because of safety treatment.

Double or triple laminated layers: Adds cost and increases safety.

Whether it's for an indoor privacy panel or a high-rise curtain wall, SafinGlass makes tailored suggestions according to intended use.

3. Lamination Interlayer Type: PVB against EVAA modest but significant cost factor is the decision between EVA (Ethylene Vinyl Acetate) and PVB (Polyvinyl Butyral):

PVB: Classical, inexpensive, gives superior acoustic insulation.

EVA: Little more pricey, ideal for decorative finishes and moisture-resistant.

EVA is sometimes chosen for metal mesh applications because of its great bonding with metal and clarity retention.

4. Personalised Patterns and BrandingIf your project calls:

Custom geometric designs

Architectural topics One of the most costly pieces, this also provides your project a special look.

5. Order volume and panel sizeGreater sizes mean more material and handling costs, while volume orders usually cut unit costs. Oversized panels, meanwhile, need particular handling and storage. Custom management could raise labor costs.

To maximize material use and manage expenses, we advise batch planning for big projects at SafinGlass.

6. Edge Finishing and HandlingParticulars include:Hole drilling for lighting, Chamfering, CNC cut, Beveling. Add great value and sophistication but also labor and equipment expenses. The more complicated your edge work, the more expensive the service.

7. Acoustic, Fire, and Safety RatingsIn compliance with:

Codes of National Architecture

Green Building Certification

Rules about fire-resistant goods

Tip: Always specify the level of compliance needed for your project before approving your glass configuration.

8. Installation NeedsInstallation expenses differ depending on:

Location (exterior vs interior)

Accessibility ( high-rise versus ground level)

mounting brackets, framed vs frameless

Structural loads' demands

For high-performance installations, the cost of the glass is only 60% of the entire budget; the other 40% covers framing, bracketing, sealants, and labor.

9. Freight and deliveryGlass with metal mesh needs:

Cushioned packing for long-distance transport, if applicable, is

Lift aid or on-site crane logistics

This is especially true for export orders or remote project locations. Delivery schedules, damage control, and insurance can subtly inflate the final bill.

Hidden Costs You Shouldn’t IgnoreBeyond material and installation, consider these soft costs:

Site surveys and consultations

Mock-up sample panels

Replacement policy for breakage or rejection

Extended warranties

Import duties (for imported meshes or glass)

Cost-Saving Suggestions from SafinGlass

We assist customers in saving expenses without sacrificing quality at SafinGlass. Here's how:

Bulk purchases: cheaper per-unit price and easier logistics

Local sourcing: avoids import taxes and delays.

Longer schedules provide for batch manufacturing efficiency with flexible lead times.

Reduces cutting waste through standard size optimization.

Ultimate checklist before selecting a metal mesh lamination business

Is the mesh material fit for both indoor and outdoor use?

Are you utilizing the right interlayer for durability?

Have you factored in safety and fire requirements?

Are your panel sizes cost effective?

Has the difficulty of installation been checked?

Has the vendor both technological and aesthetic execution experience?

ConclusionChoosing a metal mesh lamination service is about making an educated, balanced decision based on design objectives, performance standards, and long-term value rather than only seeking the lowest quote.

We at SafinGlass distinguish ourselves by providing perfect quality, accurately crafted metal mesh laminated glass solutions that are clear in pricing.

Need expert guidance?Visit https://safinglass.com or contact our team for a personalized consultation and quotation.