GLASS & ALUMINUM

BLOG

The Science of Metal Mesh Laminated Glass: Strength, Safety, and Style

In today's modern architecture and interior design, materials are no longer selected based on functionality alone; they're prized equally for looks and performance. Of all materials that truly capture this harmony, metal mesh laminated glass stands out as a prime example. Not only is it strong, safe, and extremely visually striking, but it's also changing the design game when it comes to transparency, light, and texture.

From luxury residences to commercial structures to art displays, metal mesh glass unites industrial toughness with sophisticated style. This technological marvel balances the strength of laminated glass with the distinctive personality of metal materials. What makes laminated glass metal mesh, however, so groundbreaking a product? Let's investigate the science, the process, and applications behind it and why expert metal mesh lamination services are necessary for realizing the ideal outcome.

What Is Metal Mesh Laminated Glass?

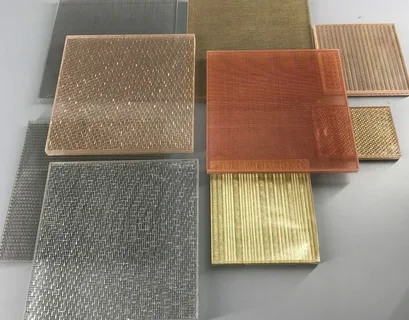

Metal mesh laminated glass is an advanced composite material in which a layer of metal mesh is sandwiched between two or more layers of glass with the use of a special lamination procedure. The mesh, which may be constructed out of stainless steel, bronze, copper, or aluminum, is sealed permanently within the glass layers under heat and pressure.

This treatment not only makes the glass stronger and more secure but also imparts a breathtaking decorative element. The infused metal mesh gives rise to elaborate reflections, patterns, and depth, endowing the glass with a dramatic yet sophisticated look.

Essentially, metal mesh lamination transforms regular glass into an operational work of architectural art blending the contemporary aesthetic of metallic materials with the clarity and adaptability of glass.

Metal Mesh Lamination Process Operation

The manufacturing of metal mesh laminated glass requires precise engineering and sophisticated technology to guarantee durability, visual transparency, and structural strength. The process generally encompasses the following steps:

Glass Preparation:Two or more sheets of quality glass are cleaned and prepared. Depending on the shape, clear, tinted, or textured glass can be utilized.

Incorporating Metal Mesh:A good metal mesh of stainless steel, copper, or bronze is inserted with care between glass sheets. The mesh type — woven, perforated, or expanded — decides both the look and transparency level.

Lamination:The metal and glass layers are joined by an interlayer like PVB (Polyvinyl Butyral) or EVA (Ethylene Vinyl Acetate). In controlled heat and pressure, the layers melt together to create a solid composite panel.

Finishing and Cooling:The metal mesh glass is cooled and trimmed after lamination. The edges are polished, and the panel is checked for clarity, evenness, and strength.

The outcome is a breathtaking, strong laminated glass metal mesh panel that's just as functional as it is gorgeous — perfect for use from facades to interior dividers.

The Science Behind Its Strength and Safety

The essence of metal mesh laminated glass is the science of lamination, a technology that significantly fortifies the glass's structure and mechanical strength.

Reinforced Structure:The metal mesh trapped inside the glass is an internal support. It evenly disperses stress throughout the surface and does not allow the cracks to extend. This renders metal mesh glass much stronger than common glass.

Shatter Resistance:Although the outside glass layer may shatter with impact, the interlayer and metal mesh keep the pieces intact. This keeps the hazardous pieces of glass from flying off, and for that reason, laminated glass metal mesh is safe to install in public and residential construction.

Fire and Heat Resistance:Depending on the material of the metal, metal mesh laminated glass provides superior fire resistance. Bronze and stainless steel meshes can resist heat well, retarding the spread of fires and keeping the panel intact upon exposure to heat.

UV and Sound Insulation:The interlayer employed in metal mesh lamination not only welds the layers together but also absorbs UV light and sound. This renders it as a practical solution for homes, hotels, and offices that want comfort and protection.

Long-Term Durability:Since the mesh is sealed within glass, it is not exposed to corrosion, water, or oxidation. In this way, metal mesh laminated glass continues to look and perform well for many years, regardless of the environment.

Aesthetic and Design Benefits:While science bestows metal mesh laminated glass with its strength, design imbues it with its soul. Architects and interior designers like this material not only for performance but also for its power to enhance aesthetics.

Dazzling Visual Texture:Metal mesh contained within the glass provides an interesting play of light and shadow. When light falls on it, the mesh glows softly, imparting depth and sophistication to any environment.

Design Options to Match Your Imagination:With expert metal mesh lamination services, customers can personalize the appearance of the glass by choosing various metal types, mesh designs, and degrees of transparency. Bronze brings warmth, stainless steel gives a sleek industrial feel, and copper adds an opulent, artistic note.

Versatile Applications:From dramatic facades to subtle interior details, metal mesh glass can be applied nearly anywhere. It offers the benefits of privacy without sacrificing light and contributes a tactile, sculptural element to walls, ceilings, and partitions.

Light and Reflection Play:The synergy of glass clarity and metal reflectance makes laminated glass metal mesh perfect to produce vibrant lighting effects. Natural and artificial light are harmoniously interacted with the incorporated mesh, altering the space's mood and tone throughout the day.

Applications of Metal Mesh Laminated Glass

Metal mesh laminated glass is among the most versatile products of today. Its fusion of sophistication and functionality qualifies it for use in both interior and exterior designs, including:

- Building Facades: Provides texture and solar shading with a sleek, modern appearance.

- Interior Partitions: Provides privacy with a rich, semi-transparent finish.

- Balustrades and Railings: Provides safety while making a striking design statement.

- Ceilings and Skylights: Adds an industrial but sophisticated appearance to architectural interiors.

- Doors and Wall Panels: Ideal for upscale hotels, offices, and homes.

- Retail Displays: Emphasizes products in a visually appealing and contemporary setting.

- Improved Safety: Shatter-resistant and safeguards occupants against injuries.

- Design Flexibility: Extensive selection of material, finish, and pattern.

- Durability: Weather, UV, and corrosion resistant.

- Acoustic and Thermal Insulation: Provides quieter, more energy-conserving interiors.

- Luxury Aesthetic: Delivers sophistication and a futuristic look to any design.

The fact that it can combine strength with artistry is what distinguishes metal mesh lamination from conventional glass solutions.

Why Expert Metal Mesh Lamination Services are Important

Manufacturing perfect metal mesh laminated glass calls for precision engineering and expertise. Professional metal mesh lamination services guarantee the process is executed at the right temperature and pressure for uniform adhesion and transparency.

Here's why hiring experts is essential:

- Quality Assurance: Experienced teams uphold rigorous quality control for durability and aesthetic uniformity.

- Customization: They provide bespoke laminated glass metal mesh designs to meet individual architectural requirements.

- Safety Compliance: End products are compliant with local and international building codes.

- Innovation: Seasoned fabricators may also blend metal mesh with colored interlayers, lighting components, or special coatings for added functionality.

Simply put, expert services guarantee that each metal mesh glass installation not only appears exquisite but also works perfectly in the long run.

Conclusion:Metal mesh laminated glass is the ideal combination of engineering and design — a material that provides strength, safety, and unparalleled style. With advanced metal mesh lamination, glass transcends transparent surfaces; it becomes an expressive architectural feature that engages with light and space in unparalleled ways.

Whether you're building a state-of-the-art corporate headquarters, contemporary home, or high-end retail environment, laminated glass metal mesh offers a clean balance of form and function. And with superior metal mesh lamination services, you can guarantee every installation sets new standards for quality, performance, and visual excellence.

In a world where materials shape architecture, metal mesh glass is a beacon of modern innovation — robust, secure, and irresistibly fashionable.