GLASS & ALUMINUM

BLOG

A Step-by-Step Guide to Selecting the Ideal Metal Mesh Lamination Service Provider

If you're seeing this, you're probably undertaking a project that requires a contemporary, fashionable and robust solution such as metal mesh laminated glass and now you're looking around wondering where to begin. To start with, excellent choice! Metal mesh lamination isn't cool just because it's fashionable; it's wise. Finding the right metal mesh lamination service provider, though? That's a different ball game altogether.

The market is saturated with metal mesh lamination companies but they are not all the same. There are some who will woo you with fancy samples and a lot of talk, but when it comes to actual performance quality, on-time delivery and service they fall flat.

So how do you make the correct decision? In this guide , we're taking it step by step in clear, straightforward language. No jargon. No nonsense. Just sound advice to produce the results you want.

First Things First What Is Metal Mesh Lamination?

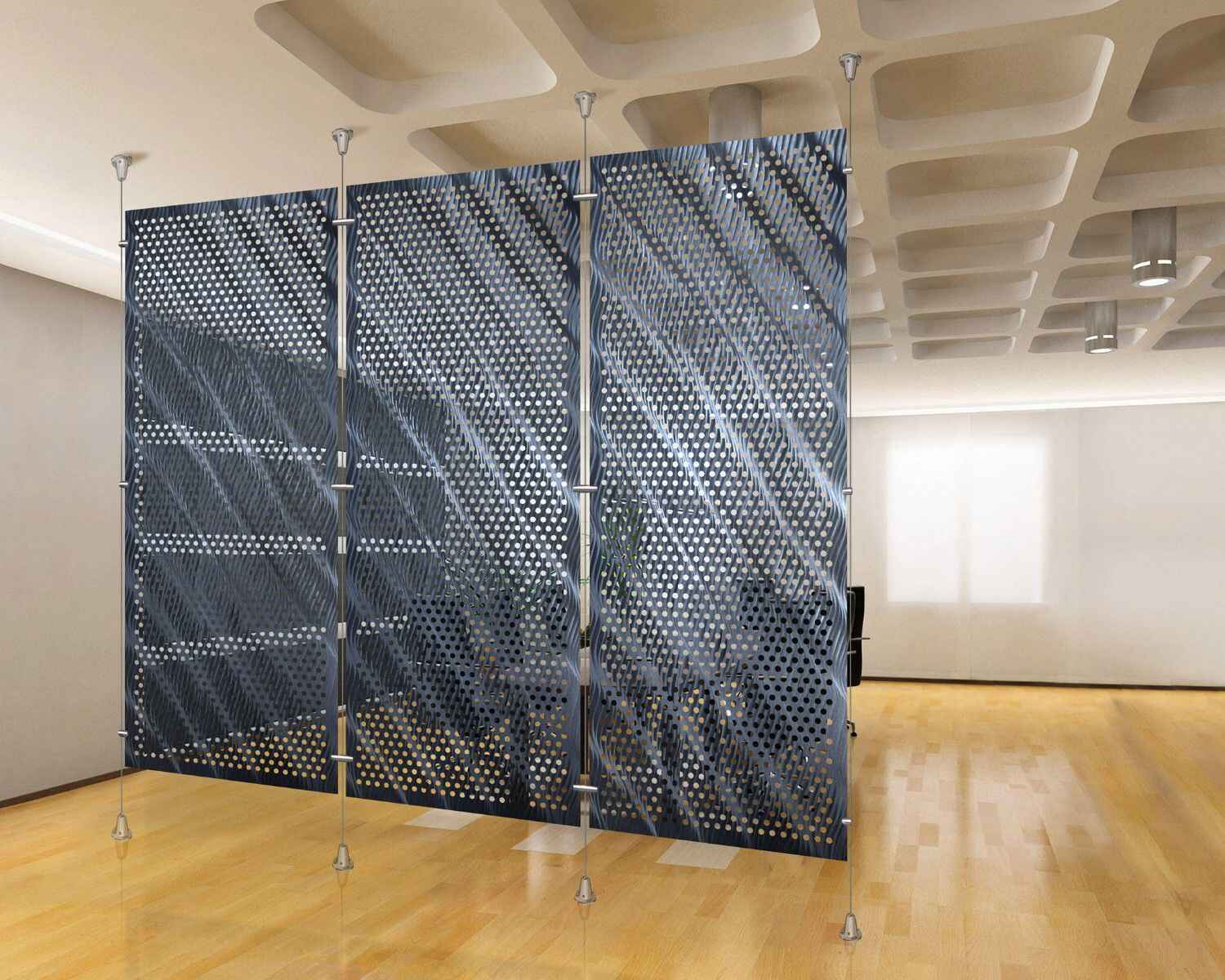

Let's begin with the fundamentals. If you're new to this world, metal mesh lamination is the process of placing a thin layer of metal mesh, imagine stainless steel, copper or bronze between two or more pieces of glass (or other materials). The outcome is what we refer to as metal mesh laminated glass.

Picture a sandwich: glass on the outside, metal mesh in the middle. It's as sleek and powerful as it sounds.

This process results in a product that's not only stunning to behold but also high performance when it comes to safety, durability and privacy. Whether for an office, hotel, restaurant, elevator, railing or even home feature wall, metal mesh glass is a statement.

Why It's So Popular Right NowHere's why architects, designers and builders adore metal mesh glass so much:

Stylish: It boasts a contemporary , industrial feel that goes perfect with minimalist style.

Safe: When the glass is broken, the mesh assists in keeping it intact, no hazardous shards scattered everywhere.

Durable: It can withstand heavy use, so it's ideal for busy areas.

Customizable: Select various types of mesh, finishes, and glass sizes to match your project.

But all these advantages are only apparent if the metal mesh lamination service is properly executed. And that's where selecting the correct provider becomes such a big deal.

Step 1: Define Your Project NeedsBefore you call anyone, take a step back and clarify what you require. Ask yourself :

Where will the glass be installed? Indoor wall? Outdoor facade? Elevator?

What dimensions and thickness do you require?

Do you have a favorite mesh material or pattern?

Is the project more focused on aesthetics, safety or both?

Do you require custom finishes such as bronze or black stainless?

What's your timeline?

Having the answers to these questions will enable you to communicate effectively with service providers and receive accurate quotes.

Step 2: Research Their ExperienceNot all glass companies do metal mesh laminated glass. You need someone who specializes in this specialized area , not someone who's experimented with it.

Ask them:

Do you have samples of previous metal mesh lamination projects?

Have you consulted with designers or architects on similar installations?

May I see photos or tour a completed project?

Their portfolio will be evidence enough. If they can't present you with some actual examples, that's a red flag.

Step 3: Query the MeshThis is where it gets slightly technical but don't panic, we'll keep it basic.

Not all metal mesh is equal. It's available in varying:

Materials: Stainless steel, bronze, copper, aluminum.

Patterns: Woven, crimped, flat, decorative.

Finishes: Brushed, matte, powder coated, colored.

Open areas: More open or tighter weave impinges on privacy and transparency.

Your service provider ought to be able to walk you through picking the perfect one for your design and function objectives. If they simply hand you a catalog and say, Choose one! it's not the right fit.

Step 4: Understand Their ProcessGood metal mesh lamination services have a meticulous process to ensure quality. Don't be afraid to ask them how.

What interlayer do they employ? (PVB, EVA, or SGP are typical; each has advantages and disadvantages.)

Do they employ autoclaves (industrial pressure and heat machines) to eliminate air bubbles?

What is their quality control process?

A professional supplier will guide you through every step and tell you why their method produces better outcomes.

Step 5: Check Certifications and Safety StandardsIf you are using the glass in a building, particularly commercial or public buildings, safety requirements are an absolute necessity. Your metal mesh laminated glass must pass certifications such as:

ANSI Z97.1 (US)

EN ISO 12543 (Europe)

AS 1288 (Australia)

And any building codes specific to your location for safety in glass

Ensure your supplier tests their products and issues documentation to support it.

Step 6: Request SamplesYou should always, always ask for a sample. It's easy to look at pictures but then there's having it in hand.

If you receive a sample , inspect it for:

Clarity: Is the lamination clear and bubble-free?

Mesh placement: Is it evenly and properly centered?

Edge finishing: Are edges smooth and secure?

Color accuracy: Does the mesh finish appear as you envisioned?

You wouldn't want any surprises when the finished order arrives.

Step 7: Obtain a Transparent QuoteYour reliable provider will provide you with a transparent, itemized quote containing:

Glass size and thickness

Mesh type and finish

Lamination type (EVA, PVB, SGP)

Edge finishing (polished, beveled, etc.)

Lead time

Shipping or delivery charges

Installation support (if applicable)

Be careful of nebulous prices such as "per square foot" with no specifics. That usually translates to surprise expenses down the road.

Step 8: Inquire About Lead TimesGood things take time and laminated glass metal mesh is not an exception. Ask up front how long it will take:

To make samples

To produce full-on

To deliver or install

Lead times can range from 3 weeks to 8 weeks or more depending on complexity , so factor that into your planning.

Step 9: Consider Their Customer ServiceWhen you’re dealing with custom materials like metal mesh glass , things can cause delays , design changes or unexpected site conditions. That’s why working with a provider who’s responsive and helpful is so important.

Do they reply to your calls or emails promptly?

Do they respond clearly and helpfully to your questions?

Do they explain it in plain English?

Will they offer after-sale service if something goes wrong?

You need a partner, not a product.

Step 10: Check Reviews or Get ReferencesFinally, see what others have to say. Find:

Online reviews (Google, Yelp, etc.)

Testimonials on their own website

Testimonials from previous customers (particularly architects, builders, or designers)

If other people had an excellent experience with their metal mesh lamination service, that's a good indication you're in capable hands.

Last WordsFinding the best metal mesh lamination service company to partner with doesn't have to be a hassle but it does require some homework. The value of your end product is highly dependent on the person you work with.

With the right partner, your metal mesh laminated glass will not only meet your expectations, it'll exceed them.

If you’re just starting your search or narrowing down options, use this guide as your checklist. And remember, quality, clarity and service matter more than just the cheapest price.